wafer process technology consulting

wafer fabrication

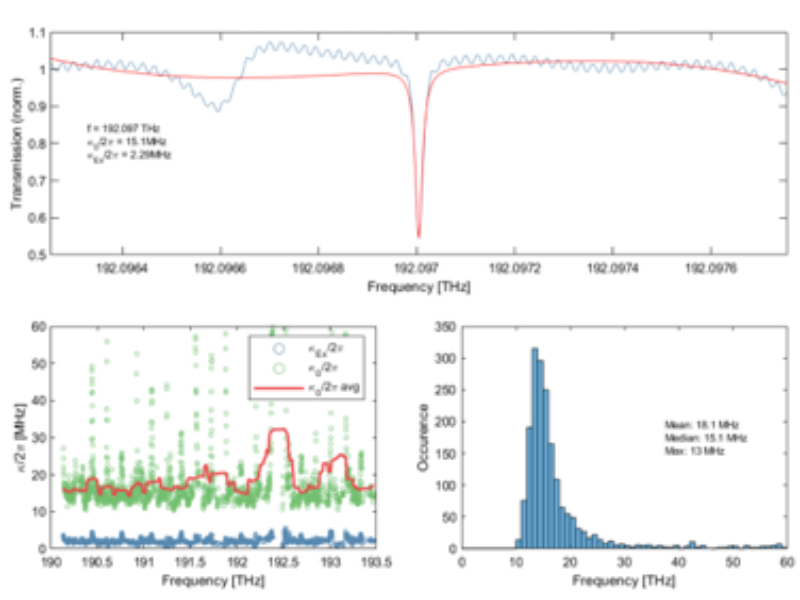

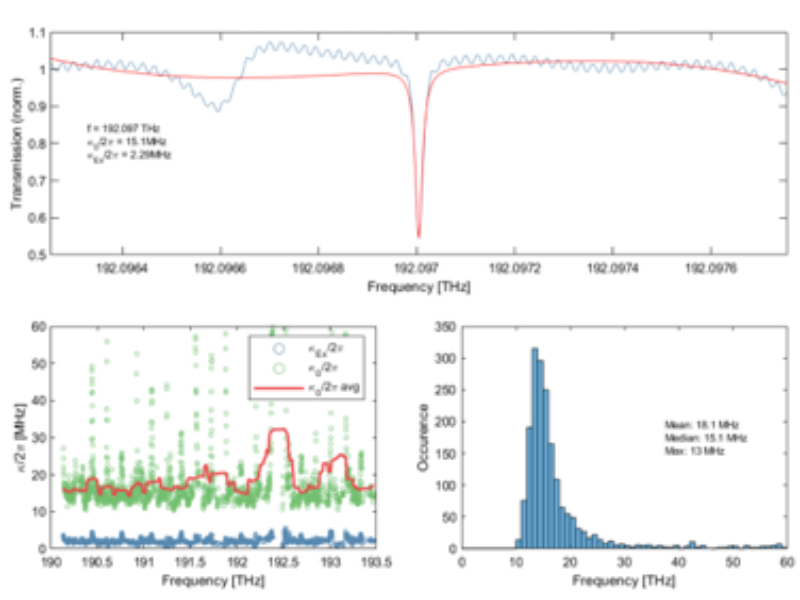

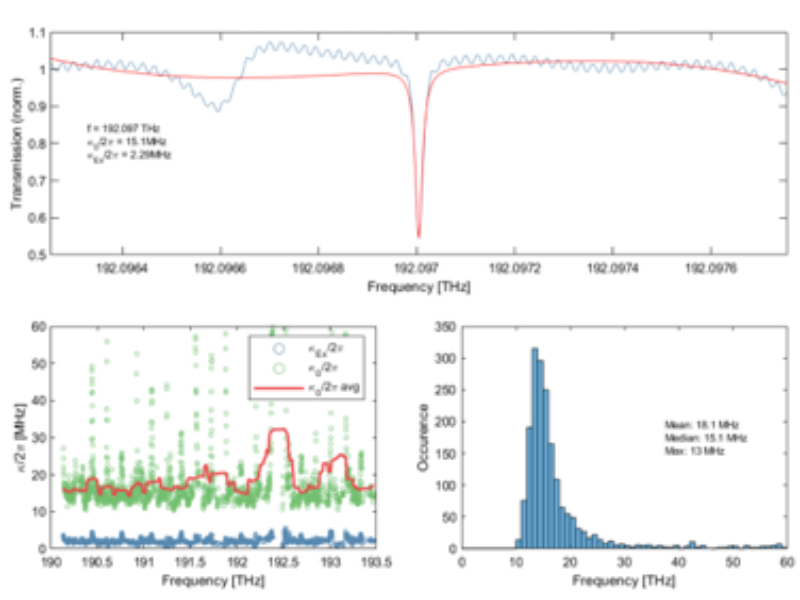

Ultra-Low Loss Si3N4 Micro-Ring Resonators (MRRs) Fabricated on Our 200 nm to 800 nm Platform

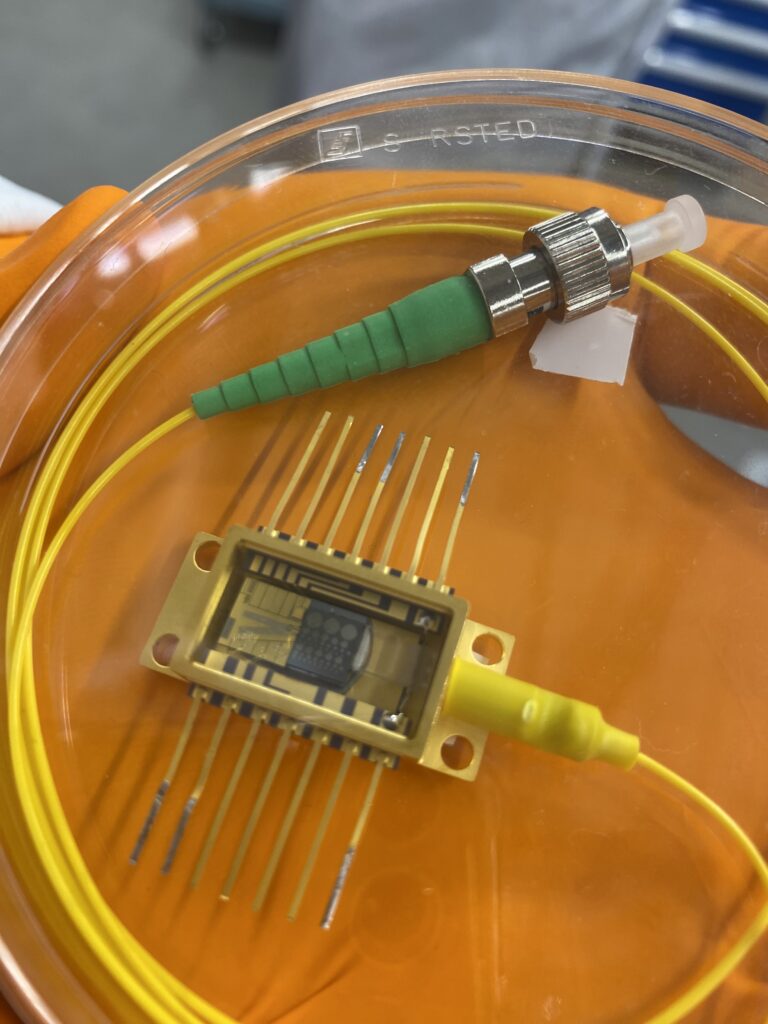

At QFAB, we specialize in Multi-Project Wafer (MPW) fabrication services, delivering state-of-the-art photonic devices without handling design. Our advanced foundry processes enable ultra-low loss performance, as demonstrated by this typical high-Q Si3N4 MRR test data at ~1550 nm wavelength.

LithiumNiobate

At QFAB, we specialize in Multi-Project Wafer (MPW) fabrication services, delivering state-of-the-art photonic devices without handling design. Our advanced foundry processes enable ultra-low loss performance, as demonstrated by this typical high-Q Si3N4 MRR test data at ~1550 nm wavelength.

LithiumTitanite

At QFAB, we specialize in Multi-Project Wafer (MPW) fabrication services, delivering state-of-the-art photonic devices without handling design. Our advanced foundry processes enable ultra-low loss performance, as demonstrated by this typical high-Q Si3N4 MRR test data at ~1550 nm wavelength.

Si3N4+LiNbO3 (LiTi)

At QFAB, we specialize in Multi-Project Wafer (MPW) fabrication services, delivering state-of-the-art photonic devices without handling design. Our advanced foundry processes enable ultra-low loss performance, as demonstrated by this typical high-Q Si3N4 MRR test data at ~1550 nm wavelength.

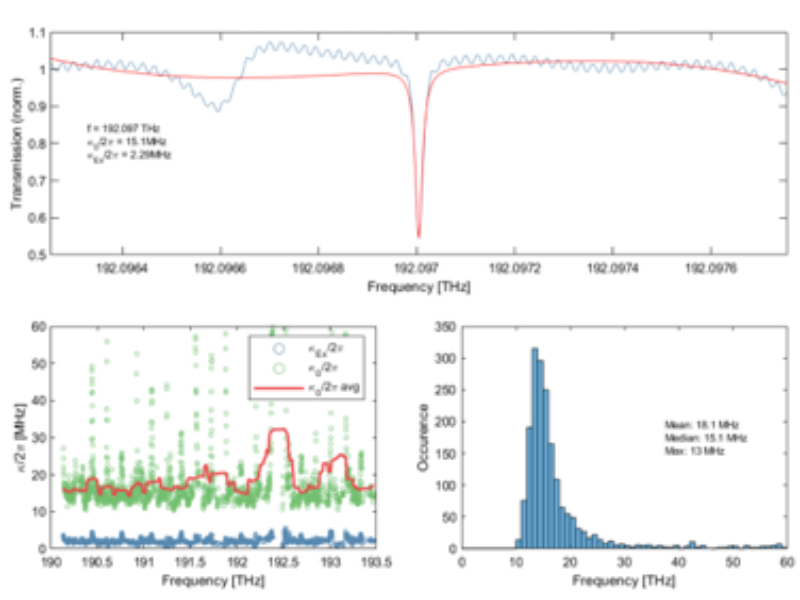

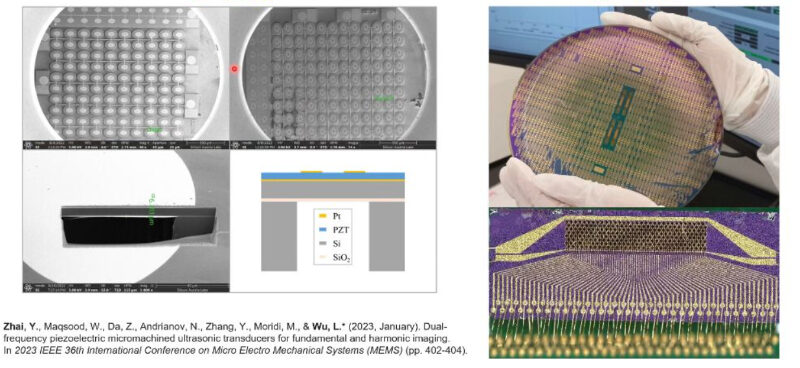

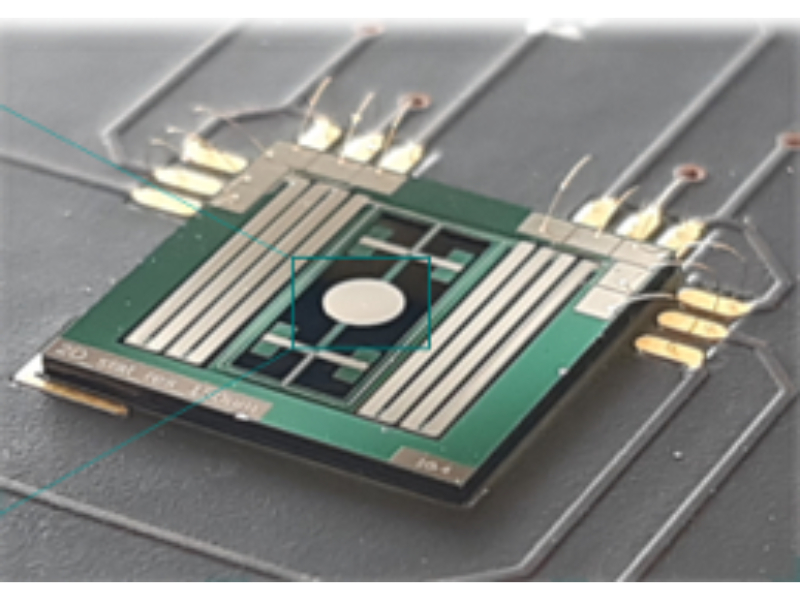

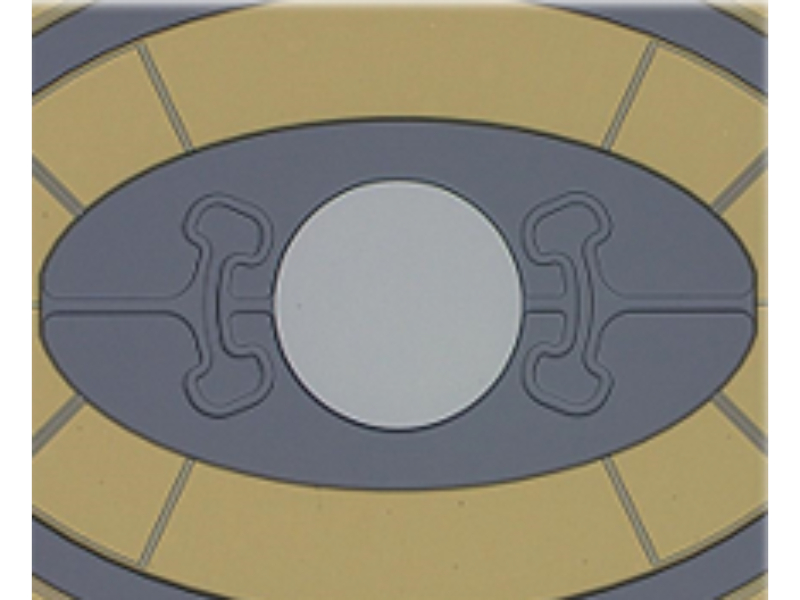

QFAB Foundry: Advanced Piezoelectric MEMS & Hybrid MEMS-PIC Integration Capabilities

At QFAB, we deliver world-class open-foundry services for piezoelectric micromachined ultrasonic transducers (PMUTs) and hybrid MEMS-Photonics integration. Our proven processes enable cutting-edge devices from research prototypes to volume production.

Highlight: Dual-Frequency Piezoelectric PMUT for Fundamental & Harmonic Imaging

(Published in IEEE MEMS 2023 – Top Conference in the Field)

We successfully fabricated a single-element oval-diaphragm PMUT that simultaneously operates in two distinct frequency bands from one vibrating membrane — a breakthrough verified by real ultrasonic imaging experiments.

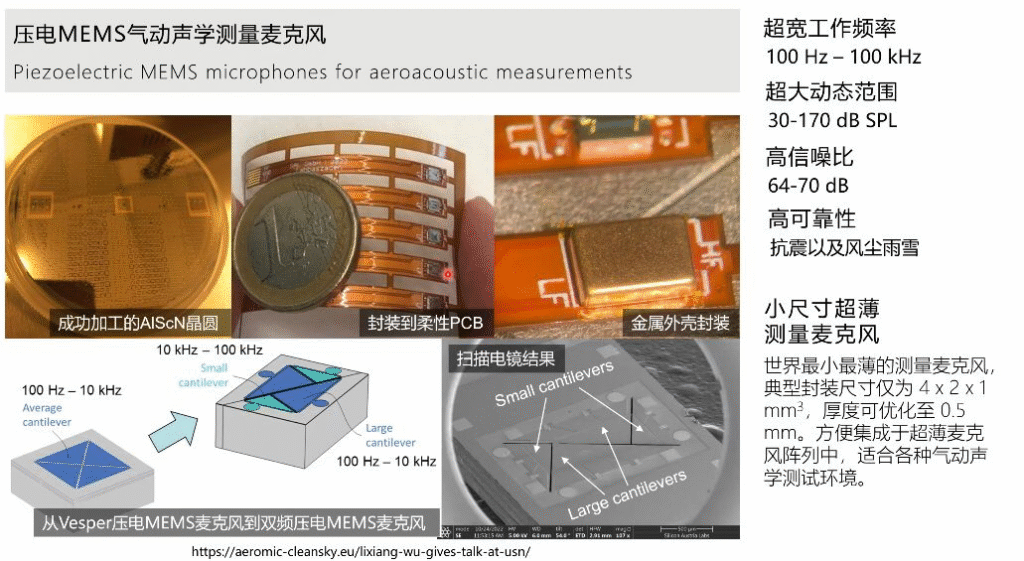

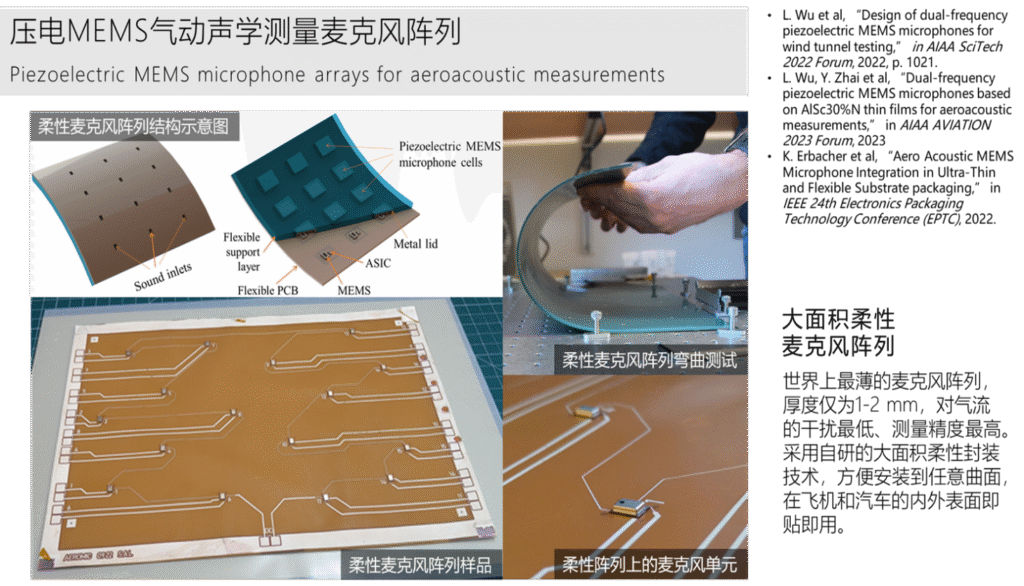

Dual-frequency Aluminum Scandium Nitride piezoelectric microphones with wide bandwidth, large dynamic range, and high sensitivity for wind tunnel testing

https://ieeexplore.ieee.org/abstract/document/10516769

World’s Highest-Performance Dual-Frequency AlScN Piezoelectric MEMS Microphone for Aeroacoustic Wind-Tunnel Testing Silicon Austria Labs (SAL) + University of South-Eastern Norway First author: Dr. Yanfen Zhai

Extreme Fabrication Challenge – Perfectly Delivered

Full 4-inch SOI wafer, complex 8-mask high-precision process including deep backside cavity, vapor HF release, and stress-controlled AlScN/Mo multilayer stack

First-ever 30 % scandium-doped AlScN (AlSc30%N) thin-film MEMS microphone

Dual cantilever design (0.94 mm² + 0.36 mm²) on single chip covering two frequency decades

World-Class 2D Piezoelectric MEMS Micro-Mirrors & Full Turnkey Service

(From Prototype to Volume Production – We Design + We Fab)

QFAB has successfully developed and fabricated high-performance 2D piezoelectric MEMS micro-mirrors that rival and exceed current industry benchmarks. Our mirrors are already proven in real laser beam steering systems and deliver.

Applications We Serve

- Automotive AR-HUD (windshield & near-field projection)

- Smart/AR glasses & wearable light engines

- LiDAR & 3D sensing

- Pico-projectors, industrial laser marking, biomedical imaging

We do everything from your idea to delivered wafers:

concept → simulation → layout → MPW proof-of-concept → design freeze → dedicated volume runs.

QFAB – Your Single-Chip Solution for Piezoelectric-Tuned Photonics

Target Applications

- Tunable narrow-linewidth lasers & microwave photonic oscillators

- Reconfigurable photonic integrated circuits (ROADMs, optical switches)

- Ultra-linear phase modulators for coherent communication and RF photonics

- Chip-scale LiDAR beam steering with piezo + photonics

- Quantum photonics with fast piezo-tuned cavities

One Partner, One Process, 200 mm wafers, MPW shuttles, dedicated runs

You bring the idea – we deliver the fully integrated, piezo-electrically tuned photonic chip with world-class optical and actuation performance.

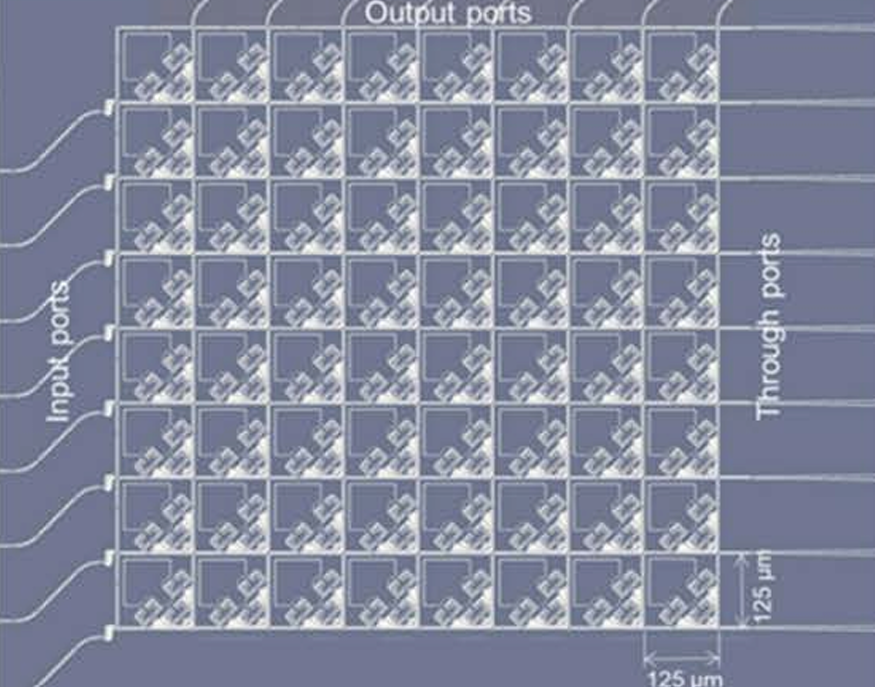

QFAB – World’s Smallest Silicon Photonic MEMS Switch Array

(Optics Express 2018 – Still the Global Size Record in 2025)

- Single switch cell: 125 × 125 μm – world’s smallest ever reported

- Full 8×8 non-blocking matrix: 64 switches in just 1 × 1 mm

- 100 % first-wafer yield across the entire lot

- 109 nm coupling gap precision via lateral comb-drive

- < 1 dB insertion loss │ > 16 dB crosstalk │ 36.7 μs switching │ > 1 billion cycles

All designed and fully fabricated in-house on a 250 nm SOI single-mask, two-etch process.

When the target is the absolute limit of integration density and yield, only one foundry has already done it on the very first wafer.

QFAB – We turn record-breaking nanophotonic MEMS into reality.

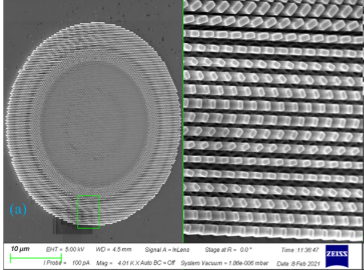

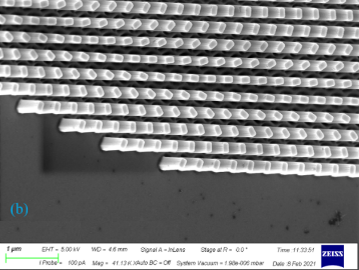

QFAB – Gallium Nitride Metasurface Foundry

World-Class GaN-on-Sapphire | GaN-on-Silicon | AlGaN/GaN Platforms

Turnkey Service

Custom metasurface design

→ DUV/E-beam lithography → GaN nano-fabrication → MPW shuttles → dedicated volume runs

When the world needs the highest-index, most precise, wafer-scale GaN metasurfaces, only one foundry has already shipped them at scale.

QFAB – GaN Metasurface Foundry of Record

micro and nano – fabrication service

photo lithographie

Precision Lithography Foundry – 10 nm to 100 nm, 4″ to 8″ Wafers

QFAB offers a comprehensive in-house lithography suite, seamlessly integrating 200 kV electron beam lithography (≤ 10 nm resolution, ideal for metasurfaces and quantum photonics), 193 nm DUV immersion stepper (100 nm features for 4″ to full 8″ volume production of TFLN, InP, and MEMS PICs), maskless laser direct writing (≥ 300 nm for rapid prototyping and microfluidics), and double-side contact/projection aligners (≥ 0.8 µm with sub-micron front/back alignment for MEMS and bonding). All processes share unified design rules and metrology, ensuring zero-risk transitions from 10 nm R&D to 100 nm high-yield 8-inch runs. When precision, scale, and reliability matter, QFAB delivers unmatched lithographic flexibility.

Main Function:

QFAB delivers the world’s broadest lithography portfolio — from ≤10 nm EBL to 100 nm full 8-inch DUV stepper — enabling seamless transition from ultimate-resolution research to high-yield volume production in a single foundry.

etching

Industry-Leading Dry Etching for Piezoelectric & Photonic Thin Films

Full 4-inch → 8-inch (plus chip/piece) capability with the most complete dry-etch portfolio for LiNbO₃, LTO, PLZT, PZT, AlN, ScAlN, quartz, and all piezo/photonic thin films:

High-rate, low-damage ICP/RIE for LiNbO₃, LTO, PZT, AlN

Ultra-smooth IBE for piezoelectric stacks and metals

Scallop-free DRIE for high-aspect-ratio piezo structures

Stiction-free vapor-phase HF / XeF₂ release

Uniformity <1.5 % (3σ), sidewall roughness <1.5 nm RMS, damage-free profiles — proven across full 200 mm wafers.

Main Function:

QFAB delivers damage-free, ultra-precise dry etching (ICP/RIE/DRIE/IBE/vapor HF & XeF₂) of LiNbO₃, LTO, PLZT, PZT, AlN, AlScN, Si₃N₄, SiO₂, metals (Al/Ti/Ta/W/Au/Cu), and all related photonic/piezoelectric stacks from single chips to full 8-inch wafers.

medium-current ion implantation service

Wafer size: 4, 6, 8, 12 inch and non-standard/custom shapes

Energy range: 5 – 210 keV

Dose range: 5×10¹¹ – 1×10¹⁷ ions/cm²

Implant angle: Tilt 0°–60°, Twist 0°–359° (full 4-axis control)

Supported species: H, He, P (other species available on request)

Compatible substrates: SiC, Si, LiNbO₃, LiTaO₃, diamond, LNOI/LTOI, quartz

Main Function:

QFAB performs controlled doping and material modification of H, He, and P in SiC, LiNbO₃, LiTaO₃, diamond, and silicon substrates up to 12-inch using medium-current ion implantation.

precision back-grinding & stress-relief service

4–8 inch Wafers

Starting thickness: ≤ 2200 µm

Final TTV: < 1 µm (200 mm wafer)

Surface finish:

– Si, LiNbO₃, LiTaO₃, SiO₂, YAG: Ra < 10 nm

– 4H/6H-SiC (mono- & polycrystalline): Ra < 3 nm

Compatible materials: SiC, Si, LN, LT, LNOI, quartz, sapphire, YAG

Full stress-relief and sub-surface damage removal options (wet etch / dry polish)

Main Function:

QFAB provides high-precision back-grinding and surface finishing for 4–8 inch SiC, LiNbO₃, LiTaO₃, and related substrates to achieve sub-micron TTV and nanometer-scale roughness, enabling thin-wafer packaging, reduced thermal resistance, and improved device-level heat dissipation.

chemical mechanical polishing (CMP) service

4–8 inch Wafers

Wafer size: 4, 6, 8 inch

Thickness range: 290 – 1100 µm

Surface roughness: Ra < 0.2 nm (polycrystalline SiC Ra < 0.5 nm)

Removal control: < 40 nm total thickness variation across wafer

Compatible substrates: monocrystalline and polycrystalline SiC, Si, LiNbO₃ (LN), LiTaO₃ (LT), SiO₂, LNOI, bonded stacks, and other composite materials.

Main Function:

QFAB provides production-grade CMP to planarize and polish thin films on 4–8 inch wafers, delivering sub-ångström roughness and sub-40 nm thickness uniformity for photonic, piezoelectric, and compound-semiconductor devices.

high-temperature LPCVD furnace suite

4-inch to full 8-inch (200 mm) capability

Stress-tuned Si₃N₄ (tensile/compressive, 10–800 nm) with refractive index 1.98–2.05 @ 1550 nm

HTO (High-Temperature Oxide) and LTO (Low-Temperature Oxide) with <1 % within-wafer uniformity Ultra-low stress and strain-gradient nitride for suspended membranes, waveguides, and photonic crystals Poly-Si, amorphous Si, and high-temperature anneal (>1100 °C) in the same cluster

Hydrogen-free processes for CMOS-compatible and LiNbO₃-safe deposition

From ultra-low-loss Si₃N₄ photonics to high-quality gate/passivation oxides – all with volume-ready uniformity on full 200 mm wafers.

Main Function:

QFAB delivers stress-controlled LPCVD Si₃N₄, HTO, LTO, poly-Si, and high-temperature annealing with atomic-level uniformity across 4–8 inch wafers for photonics, MEMS, and piezo-electric platforms.

precision wafer dicing & advanced shaping

4-inch to 8-inch Full-Service Dicing Platform

Plasma-based Stealth Dicing: zero-chipping, kerf-free, ultra-thin die separation for LiNbO₃, LTO, SOI, GaN, SiC and fragile thin-film stacks

Irregular / Custom Shape Dicing: free-form, curved, hexagonal, multi-radius, or any complex geometry with micron precision

High-speed blade dicing, DBG, and multi-project panelization also available

Die strength > 750 MPa routinely achieved on 50 µm thin LiNbO₃

From standard rectangles to fully custom contours on the most delicate photonic/piezoelectric wafers – QFAB cuts what others won’t.

Main Function:

QFAB provides chipping-free stealth dicing and fully custom-shaped die separation (any geometry) for 4–8 inch fragile compound, piezoelectric, and photonic wafers.

room temperature bonding

Wafer Size: 4, 6, 8 inch

Wafer Thickness: <1000µm

Alignment Accuracy: X,Y≤70µm、θ≤0.2deg

Bonding Energy: 1.0-2.0 J/m²

Processed Wafer Types: 4H-SiC, Poly- SiC, Si, SiO₂, LT, LN, Quartz, Glass, Sapphire, InP, YAG, GaAs,etc.

Main Function:

Homogeneous and Heterogeneous Material Bonding

hydrophilic/ hybrid bonding

Wafer Size: 6, 8 inch

Wafer Thickness: 6inch≤700µm 8inch≤800µm

Wafer Thickness: 1.4 – 2.0 J/m²

Processed Wafer Types: Si, SiO₂, LT, LN, InP, GaAs, SiN,etc.

Main Function:

Homogeneous and Heterogeneous Material Bonding

thermocompression anodic bonding

Wafer Size: 4, 6, 8, 12 inch

Wafer Thickness: 0.3 – 3mm

Alignment Accuracy: ≤ 0.5mm (mechanical alignment), ≤ 2μm (optical alignment)

Bonding Energy: ≥ 2.0 J/m²

Processed Material Types: Si, Au, Ag, Cu, AuSn, AlGe, SnAg, AuGe, AuIn, AuSi,etc.

Main Function:

Thermocompression bonding of metallic materials, eutectic material bonding, anodic bonding

ion beam polishing and etching machine

Wafer Size: 4, 6, 8 inch

Wafer Thickness: 400 – 1000μm

Equipment Capability: Increase THK sigma by more than 3 times (SiO₂ THK Range < 10Å; LT0I/LN0I range < 100Å; SiC0I range < 1000Å. The range is affected by the previous value of the film – layer material)

Processed Wafer Types: SOI, SiO₂, SiC composite substrates, LNOI, LTOI and other film – coated materials

Main Function:

Etching various thin – film materials and performing film – thickness adjustment

high-uniformity copper electroplating for photonic & MEMS interconnects

Void-free copper filling of high-aspect-ratio TSVs, trenches and pillars

Thickness capability from <1 µm to >100 µm in a single step

Multi-layer 3D interconnects with seamless via-chain stacking

Within-wafer uniformity ≤ 2 % (1σ), wafer-to-wafer ≤ 1.5 %

Compatible with LiNbO₃, LTO, SOI, InP, glass and thinned 8-inch wafers

Ultra-low stress (<30 MPa) and high-purity (>99.99 %) copper for photonic redistribution layers (RDL), MEMS coils, and superconducting structures

From thin seed enhancement to 100 µm+ thick power routing – QFAB delivers the industry’s most reliable copper electroplating for next-generation hybrid photonic devices.

Main Function:

QFAB provides void-free, ultra-uniform copper electroplating up to >100 µm thickness with multi-layer 3D interconnect capability on 4–8 inch photonic, piezoelectric, and compound-semiconductor wafers.

advanced PVD: sputter & e-beam evaporation

4-inch to Full 8-inch (200 mm) Volume-Ready Platform

Reactive & co-sputtering of PZT, AlN, ScAlN, LiNbO₃, SiO₂, Al₂O₃, TiO₂, ITO, HfO₂, Ta₂O₅ (<0.8 % 1σ uniformity)

Precision metals & alloys: Al, Cu, Ti, Ta, Au, Pt, Ni, Cr, W, Mo with stress control ±10 MPa

Multi-pocket e-beam evaporation for refractory metals, lift-off stacks, and high-purity superconducting films

Low-temperature (<150 °C) processes fully compatible with LNOI, InP, and thinned wafers

Single-run capability for seed layers, RDL, electrodes, AR coatings, and complex piezo stacks

Main Function:

QFAB provides volume-qualified sputter and e-beam evaporation of piezoelectrics, III-V compounds, metals, and high-k/refractory dielectrics with atomic-level control across 4–8 inch wafers for photonics, MEMS, and quantum applications.

wafer-scale nanoimprint lithography (UV-NIL & thermal)

4-inch to Full 8-inch Production Platform

Resolution down to ≤ 12 nm (half-pitch) and < 30 nm routine on 200 mm wafers Overlay accuracy ≤ 5 nm (3σ) with thermal and UV-curable resists High-throughput imprint (>60 wph) for metalenses, DOEs, AR/VR waveguides, photonic crystals, and sub-wavelength gratings

Full-cycle service: master origination (EBL/stepper), working stamp replication (soft & hard), imprint + RLT, and metallization

Compatible with LiNbO₃, LNOI, SOI, quartz, glass, and flexible substrates

Defectivity < 0.1/cm², residual layer thickness < 8 nm, uniformity < 3 %

From single prototypes to 10 k+wph volume — the fastest path from sub-20 nm photonic nanostructures to market.

Main Function:

QFAB delivers turnkey, volume-ready UV and thermal nanoimprint lithography with ≤12 nm resolution, ≤5 nm overlay, and full 200 mm wafer-scale capability for photonics, metasurfaces, and AR/VR optics.

wafer-defect inspection machine

4-inch to 8-inch Automated Review & Classification

Wafer sizes: 4″ / 6″ / 8″ (290–1000 µm thickness)

Detection sensitivity: ≥ 0.2 µm particles and defects (Bright-Field, Dark-Field, and Photoluminescence modes)

Supported materials: Si, SiC, LiNbO₃ (LN), LiTaO₃ (LT), LNOI/LTOI, SOI, quartz, glass, GaN, InP, and all composite/heterogeneous photonic wafers

Full-surface macro + micro inspection, automated defect classification, and KLARF export

Integrated with our metrology cluster for instant feedback into lithography, etch, and deposition loops

Zero blind spots. Zero escapes. Every critical defect caught before it costs you yield.

Main Function:

QFAB provides automated ≥0.2 µm defect detection and classification (BF/DF/PL) across 4–8 inch Si, SiC, LiNbO₃, LiTaO₃, and all photonic/compound wafers with full traceability and process-loop integration.

Precision Wafer Trimming & Edge Profiling

Wafer size: up to 8-inch (200 mm) full wafers and non-standard shaped substrates

Thickness range: ≤ 1000 µm (starting material)

Edge trimming and chamfering with micron-level accuracy

Materials: LiNbO₃, LiTaO₃, LNOI/LTOI, quartz, sapphire, SiC, GaN, InP, SOI, glass, and all bonded or composite substrates

Clean, chipping-free edges compatible with subsequent lithography and bonding step.

Main Function:

QFAB provides accurate wafer trimming, edge profiling, and chamfering for all ≤8-inch standard and non-standard substrates, including fragile piezoelectric and photonic materials.

precision wafer flatness & geometry metrology

4-inch to 8-inch | 300–1000 µm Thickness

Dual-sided interferometric + capacitive sensing

Key parameters: TTV ≤ 0.3 µm, LTV ≤ 0.2 µm, Warp/Bow ≤ 3 µm, Thickness variation ≤ 0.5 µm (3σ across 200 mm)

Full-surface, high-density mapping (>1 million points/wafer) in <60 s

Compatible with all substrates: LiNbO₃, LTO, LNOI, SOI, SiC, GaN, InP, quartz, glass, bonded and thinned wafers

Real-time GBIR/SBIR/SFQR reporting and direct feed-forward to CMP, bonding, and lithography tools

Ensures perfect planarity for 3D integration, wafer bonding, and ultra-thin photonic devices.

Main Function:

QFAB delivers sub-micron TTV/Warp/Bow/Thickness metrology and full geometric characterization for all 4–8 inch substrates, from standard silicon to fragile piezoelectric and bonded photonic wafers.

nanoscribe-powered two-photon polymerization (TPP) 3D printing service

True Sub-Micron Direct-Write on 4–8 inch Wafers & Fibers

Equipment: Nanoscribe Photonics Professional GT2 + Quantum X align

Lateral feature size: typical 160 nm, guaranteed ≤ 200 nm

Vertical resolution: typical 400–1000 nm

Maximum single-field print volume: 500 × 500 × 300 µm (stitching-free)

Refractive index: n = 1.56 (IP-Dip / custom high-RI resists available)

Substrates: LNOI, SOI, glass, quartz, optical fiber end-faces, InP, GaN, pre-patterned chips

Proven structures: fiber-tip metalenses, high-NA freeform lenses, micro-needles, 3D photonic wire bonding, diffractive elements, photonic crystal woodpiles, AR/VR near-eye optics

Seamless integration of 3D nano-optics directly onto your photonic chips or fiber facets – from one-off prototypes to thousands of devices per wafer.

Main Function:

QFAB delivers industry-leading Nanoscribe two-photon polymerization 3D printing with ≤160 nm lateral resolution on wafers, fibers, and pre-structured photonic chips for metalenses, fiber-top optics, freeform micro-optics, and 3D heterogeneous integration.

comprehensive piezoelectric thin-film characterization lab

Full 4–8 inch Wafer Mapping | Production-Ready Accuracy

d₃₃ & d₃₁ coefficients: direct piezo-response (Aixacct TF-2000E & double-beam LVP), routine >250 pm/V for AlScN, >150 pm/V for PZT

e₃₁,eff mapping: wafer-level bending method, <3 % non-uniformity across 200 mm P-E hysteresis & fatigue: up to 1 MV/cm, >10¹⁰ cycles endurance testing

Dielectric constant & loss: 1 kHz–10 MHz, tanδ < 0.01 typical Leakage current: fA-level resolution, breakdown >8 MV/cm

Full-wafer ferroelectric uniformity mapping: 49–121 sites in <30 min

Curie temperature & phase confirmation: in-situ heating + Raman/XRD

All measurements performed with calibration traceable to PTB/NIST standards, reports accepted by leading RF filter, PMUT, and TFLN modulator customers worldwide.

Main Function:

QFAB provides full electrical and piezoelectric characterization (d₃₃, e₃₁, P-E, fatigue, leakage, dielectric) with wafer-scale mapping on 4–8 inch AlN, ScAlN, PZT, PLZT, and LN thin films for production release and process qualification.

FIB + TEM service for photonic & piezoelectric devices

TEM lamella preparation: FEI Helios G4 CX & Scios 2 DualBeam FIB

– Routine thickness ≤ 30 nm (critical for HR-TEM/STEM)

– Protective Pt/GaN-specific low-kV cleaning, <2 nm amorphous edge damage

– Site-specific cross-sections on LiNbO₃, AlScN, PZT, LNOI, InP PICs, metasurfaces

– High-throughput: 4–6 perfect lamellae per 8-hour shift

Atomic-resolution TEM/STEM:

– Thermo Fisher Spectra 300 Cs-corrected (300 kV)

– Resolution: 0.06 nm (STEM), 0.12 nm (TEM)

– Routine EELS & EDX mapping of Sc doping profile in AlScN, domain structure in LN, interface quality in LNOI stacks

Main Function:

QFAB delivers damage-free FIB TEM sample preparation (<30 nm lamellae) and atomic-resolution Cs-corrected TEM/STEM/EELS analysis on all 4–8 inch photonic, piezoelectric, and compound-semiconductor devices.

advanced surface & materials characterization suite

AFM (Bruker Dimension Icon):

– Ra < 0.1 nm on polished LN/Si₃N₄, peak-force QNM, conductive-AFM, piezo-response (PFM) wafer mapping

FE-SEM (Zeiss Gemini 500):

– Resolution 0.8 nm @ 15 kV, In-lens/SE/BSE, low-kV imaging of LNOI/TFLN without charging

EDS/EDX (Oxford X-Maxⁿ 150 mm²):

– Element mapping from B to U, Sc distribution in AlScN, interface analysis in bonded stacks

Integrated workflow: 4–8 inch wafer-capable stages, <30 min SEM→AFM→EDX cross-correlation

Main Function:

QFAB provides AFM (topography, PFM, c-AFM), high-resolution FE-SEM, and quantitative EDX analysis with full 200 mm wafer mapping for photonic, piezoelectric, and compound-semiconductor materials.

wafer series

cleanroom equipment

- wafer bonding equipment

- chip bonding equipment

- bonding auxiliary equipment

- bonding foundry